Discovering the Key Benefits of Membrane Change in Cutting-edge Layouts

In the realm of item style, the combination of membrane changes deals remarkable benefits, particularly in terms of resilience and dependability. These buttons, created with split, flexible products, endure extensive conditions and repetitive use, a vital advantage for tools revealed to extreme atmospheres.

Enhanced Durability and Reliability

Membrane layer switches are renowned for their improved durability and dependability, associates that originate from their unique building. These switches are made up of layers consisting of a visuals user interface layer, a conductive ink circuit, and a dielectric layer, all sealed against environmental factors such as moisture and dirt. Membrane Switch. This layering not only secures the interior parts yet additionally guarantees that the switch functions under a series of negative problems

Membrane layer switches also operate efficiently in a wide variety of temperature levels and are immune to resonances, making them suitable for usage in both commercial and customer applications where integrity is critical. Membrane Switch. Their durable building and construction causes less failings and upkeep demands

Personalization and Visual Adaptability

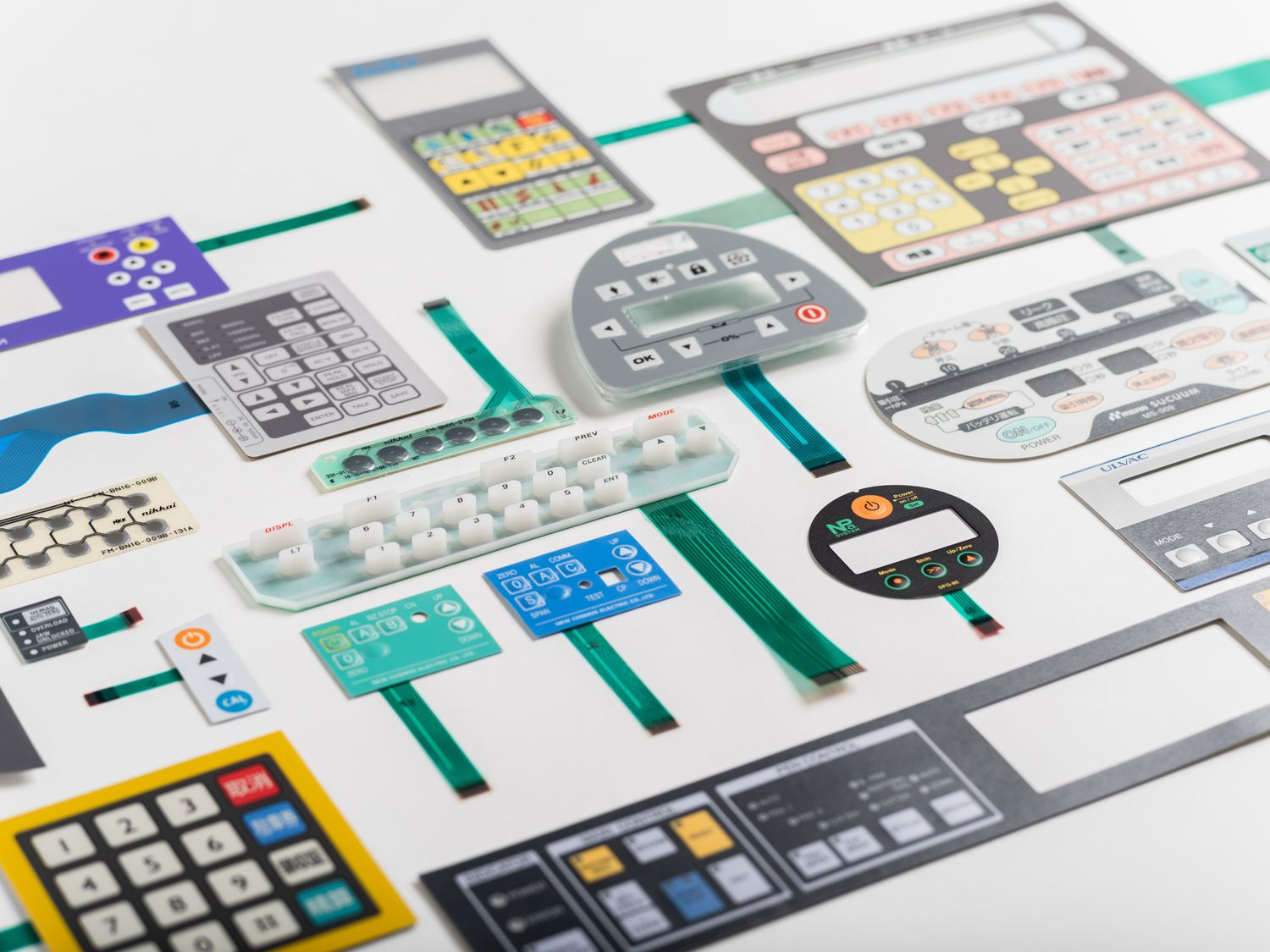

Beyond their architectural advantages, membrane layer changes offer comprehensive modification and visual adaptability to fulfill varied layout demands. Developers can customize these user interfaces to details customer requires with an array of shapes, dimensions, and shades. The visuals overlay, which is the leading layer of a membrane layer button, can be printed with custom graphics, logos, and text, making each application one-of-a-kind while adhering to brand guidelines. This degree of customization improves user communication by incorporating user-friendly style components that are very easy and visually enticing to navigate.

Additionally, the capability to incorporate clear windows for LCDs or LEDs and tactile features such as embossing improves the customer experience. These choices permit the development of a multi-dimensional interface that is not only functional yet also adds to you could look here the total item looks. By leveraging these modification capacities, producers can create distinct items that stick out in open markets.

Cost-Effectiveness and Relieve of Integration

In addition, the versatile and slim nature of membrane layer switches enables uncomplicated combination into numerous applications, from sophisticated medical devices to customer electronics. Their compact style does not require intricate setting up procedures, consequently lowering installment time and costs. Additionally, membrane buttons are compatible with many substratums and adhesives, boosting their adaptability throughout different markets. These assimilation capabilities not only simplify the layout check over here process yet also expedite the item growth cycle, making it possible for faster time-to-market for brand-new advancements.

Conclusion

In conclusion, membrane layer switches over stand out as a robust choice in ingenious layouts, offering boosted sturdiness and reliability important for enduring harsh conditions. Their capacity for modification sustains a wide variety of aesthetic preferences, making them functional for various branding needs. Their cost-effectiveness and ease of assimilation help with swift and reliable product advancement, placing membrane switches as a highly useful choice for developers intending to balance performance, style, and bankability in competitive industries.

In the world of item design, the integration of membrane changes deals notable benefits, especially in terms of toughness and integrity.Beyond their architectural advantages, membrane changes deal considerable personalization and visual versatility to fulfill diverse design requirements.While personalization improves visual allure and functionality, membrane layer buttons additionally give significant cost advantages and convenience of integration that benefit end-users and manufacturers alike. The manufacturing procedure for membrane layer changes includes less products and less labor compared to conventional mechanical switches, over at this website which directly converts right into reduced manufacturing prices.In verdict, membrane layer changes stand out as a robust alternative in cutting-edge layouts, using improved longevity and integrity crucial for enduring rough conditions.